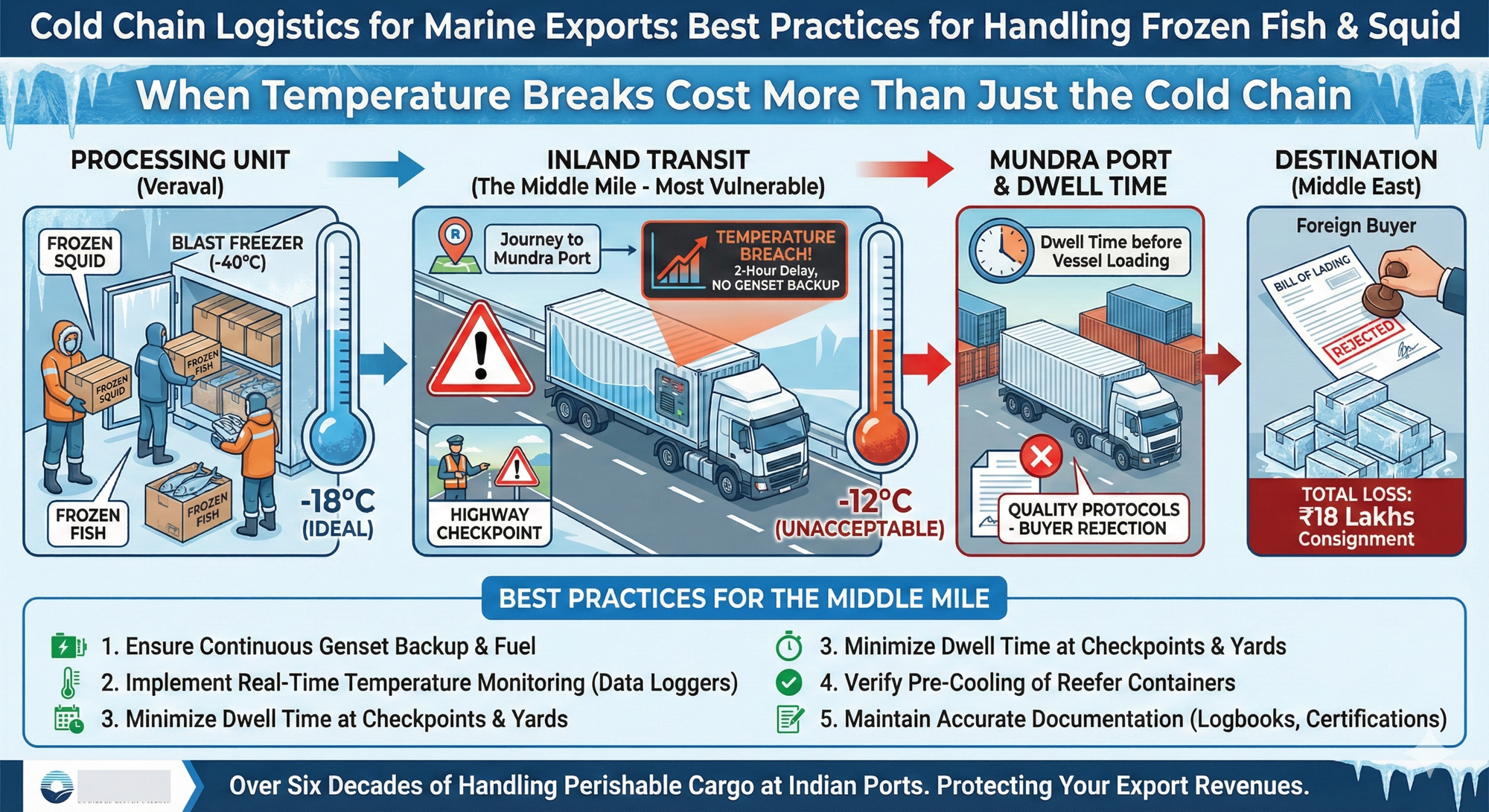

When Temperature Breaks Cost More Than Just the Cold Chain

Last month, a Gujarati exporter of frozen squid to the Middle East faced rejection of an entire consignment worth ₹18 lakhs. The reason? Temperature logs showed a breach during inland transit from the processing unit in Veraval to Mundra Port. The container was within specifications at stuffing, but a two-hour delay at a highway checkpoint without genset backup caused the product temperature to rise from -18°C to -12°C. The foreign buyer refused to accept the shipment based on their quality protocols.

Cold Chain Logistics for Marine Exports: Best Practices for Handling Frozen Fish & Squid

When Temperature Breaks Cost More Than Just the Cold Chain

Last month, a Gujarati exporter of frozen squid to the Middle East faced rejection of an entire consignment worth ₹18 lakhs. The reason? Temperature logs showed a breach during inland transit from the processing unit in Veraval to Mundra Port. The container was within specifications at stuffing, but a two-hour delay at a highway checkpoint without genset backup caused the product temperature to rise from -18°C to -12°C. The foreign buyer refused to accept the shipment based on their quality protocols.

This is not an isolated incident. In our six decades of handling perishable cargo at Indian ports, we’ve seen temperature excursions, documentation gaps, and logistical oversights wipe out entire export revenues for marine product exporters—particularly those dealing in frozen fish, shrimp, cuttlefish, and squid.

Where the Cold Chain Actually Breaks

The problem is rarely at the processing plant or at the destination port. It’s the middle mile—the journey from blast freezer to container yard, and the dwell time before vessel loading—where most failures occur.

This is not an isolated incident. In our six decades of handling perishable cargo at Indian ports, we’ve seen temperature excursions, documentation gaps, and logistical oversights wipe out entire export revenues for marine product exporters—particularly those dealing in frozen fish, shrimp, cuttlefish, and squid.

Where the Cold Chain Actually Breaks

The problem is rarely at the processing plant or at the destination port. It’s the middle mile—the journey from blast freezer to container yard, and the dwell time before vessel loading—where most failures occur.

Common Risk Points:

1. Inadequate Pre-Cooling of Containers

Many exporters assume that a reefer container set to -18°C will automatically bring the product to that temperature. It won’t. If the container isn’t pre-cooled (PTI-tested and brought down to set temperature before stuffing), you’re loading frozen cargo into a warm box. The compressor will struggle, and you’ll see temperature spikes in the first 6–12 hours.

2. Stuffing Delays and Ambient Exposure

Frozen marine products are often stuffed at Container Freight Stations (CFS) or factory premises. If pallets wait on the dock in ambient heat—even for 20 minutes—surface thawing begins. This is especially critical in coastal Gujarat, Kerala, and Tamil Nadu during summer months when temperatures exceed 35°C.

3. Poor Stowage Inside the Container

Improper blocking and bracing, or overloading beyond the reefer’s cooling capacity, restricts airflow. Cold air must circulate around the cargo. If cartons block the T-bar floor or are stacked too tightly, you’ll create warm pockets, especially in the container’s core.

4. Documentation Mismatch with FSSAI and MPEDA Norms

The Marine Products Export Development Authority (MPEDA) mandates specific documentation including health certificates, catch certificates, and processing plant approval numbers. If your Commercial Invoice, Packing List, or Bill of Lading don’t reflect the exact FSSAI plant code or batch/lot numbers traceable to MPEDA records, you risk customs holds—or worse, rejection at the destination country’s sanitary inspection.

5. Failure to Monitor in Real-Time

Most exporters rely on the carrier’s temperature data, which is only downloaded after the container reaches destination. By then, it’s too late. Without real-time GPS-enabled temperature loggers (like Berlinger, Emerson, or Sensitech devices), you’re blind to excursions during the critical first 48 hours post-stuffing.

Regulatory and Procedural Framework You Must Comply With

India’s marine export sector operates under strict oversight:

- MPEDA Registration: Mandatory for all exporters and processing plants.

- FSSAI Licensing: Your processing unit must have an FSSAI license with specific product category approvals.

- Export (Quality Control and Inspection) Act, 1963: Enforced through agencies like the Export Inspection Council (EIC), which may inspect consignments pre-shipment.

- Customs (Import of Goods at Concessional Rate of Duty) Rules, 2017 (IGCR): If you’re using duty drawback or advance authorization schemes, traceability and compliance are non-negotiable.

- International Standards: For EU exports, compliance with EU Regulation 853/2004 on hygiene of food of animal origin. For the US, FDA’s HACCP and Seafood HACCP requirements apply.

A single non-compliance—an unsigned health certificate, a missing lot number, or an expired processing plant approval—can result in detention at Indian Customs or rejection abroad.

Practical Checklist for Frozen Marine Exports

Based on PKM’s experience since 1963 handling perishable cargo at major Indian ports, here’s what works:

Before Stuffing:

- Verify reefer container has a valid PTI certificate (Pre-Trip Inspection) dated within 30 days

- Pre-cool the container to -20°C (2°C below set point) for at least 2 hours before stuffing

- Confirm genset availability for the entire inland transit route, including backup for breakdowns

- Use insulated pallets and ensure T-bar floor is unobstructed for airflow

During Stuffing:

- Minimize ambient exposure—complete stuffing within 30 minutes

- Stack cartons with 10 cm gap from container walls and ceiling (the “red line”)

- Place at least two independent temperature loggers inside the container (front and rear)

- Seal the container and set the reefer unit to continuous mode, not start-stop

Documentation:

- Cross-verify FSSAI plant code on the health certificate matches the invoice

- Ensure MPEDA consignment-wise approval (if applicable for your destination country)

- Include batch/lot traceability in packing list and cargo description in Bill of Lading

- Obtain a temperature certificate from the stuffing location (some buyers mandate this)

In Transit and at Port:

- Monitor real-time temperature via IoT loggers; set alerts for deviations beyond ±2°C

- Coordinate with your customs broker (like PKM) to ensure priority Customs examination if selected, minimizing dwell time

- Confirm vessel’s reefer plug-in schedule at the terminal; avoid containers sitting unplugged for more than 2 hours

- Obtain a captain’s receipt or mate receipt acknowledging reefer container condition at loading

What Happens When It Goes Wrong

Beyond the immediate loss of cargo value, temperature failures trigger a cascade of consequences:

- Destination Port Detention: If the consignee rejects the cargo, you’re liable for demurrage, return freight, and disposal costs.

- MPEDA Scrutiny: Repeated failures can lead to suspension of your export code or processing plant approval.

- Buyer Blacklisting: In markets like the EU, Japan, and the Middle East, reputation is everything. One bad container can close doors for years.

- Insurance Disputes: Many marine cargo policies exclude losses due to “inherent vice” or improper stuffing—your claim may be denied.

The Role of Your Customs Broker in Cold Chain Success

A licensed customs broker isn’t just a documentation facilitator. For perishable cargo, they are your first line of defense against delays.

At PKM, our role includes:

- Liaising with port authorities for priority green channel clearance under risk management systems

- Coordinating with terminal operators to ensure reefer containers are plugged in immediately upon gate-in

- Monitoring customs examination schedules to avoid weekend or holiday holds when gensets may not be monitored

- Advising on advance filing of documents (24 hours before vessel berthing) to expedite clearance under the Authorised Factory Stuffing scheme

Our legacy since 1963 has been built on understanding that for a reefer container, every hour counts.

Final Takeaway: Prevent, Don’t React

Cold chain failures are almost always preventable. The cost of a GPS logger (₹2,000–₹5,000 per trip) is negligible compared to the cost of a rejected consignment. The time spent verifying a health certificate is trivial compared to the weeks lost in dispute resolution.

Here’s what you should do today:

- Audit your last three marine export shipments—review temperature logs, documentation, and any buyer feedback.

- If you don’t have real-time monitoring, implement it for your next shipment.

- Work with a customs broker who understands perishable cargo timelines and port-specific handling protocols.

Marine exports are unforgiving of shortcuts. But with the right processes, verified compliance, and experienced logistics partners, frozen fish and squid can travel from Indian waters to global markets without a single degree of compromise.

Premji Kanji Masani Private Limited has been a licensed Customs Broker since 1963, specializing in perishable cargo clearance at Indian ports. For consultations on marine product exports, cold chain logistics, or regulatory compliance, reach out to our team.